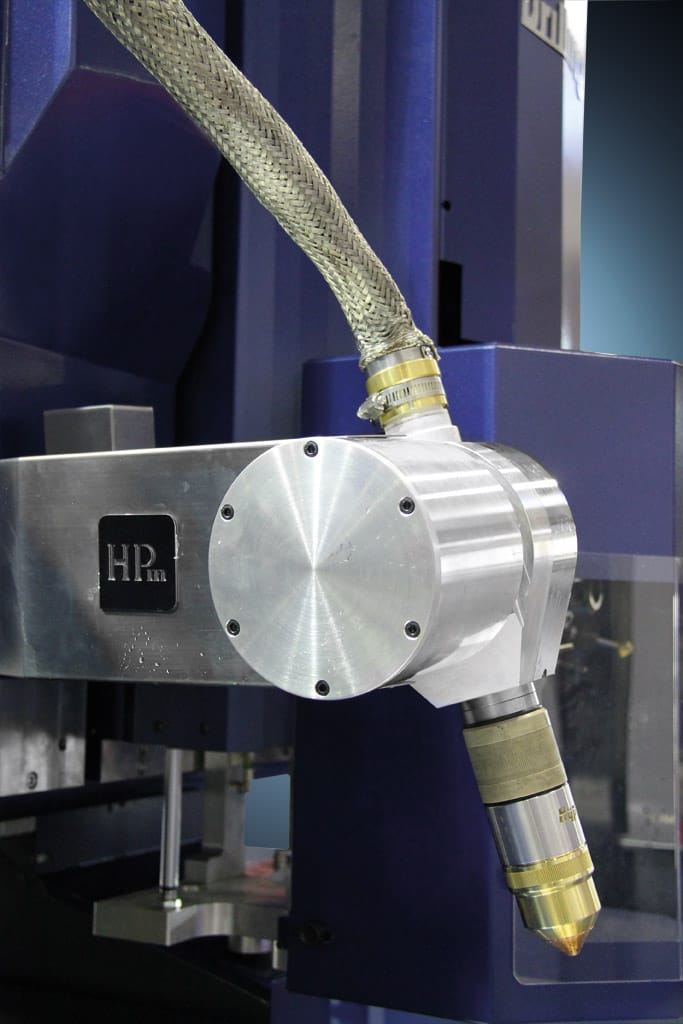

Also the Steel Max model is manufactured with a lower modular steel frame and an aluminum electrically welded gantry crossbeam, all specifically sized to support drilling tools and combined accessories.

The use of the aluminum crossbeam ensures lightness, strength and elasticity, and allows the machine to be strong, precise and fast.

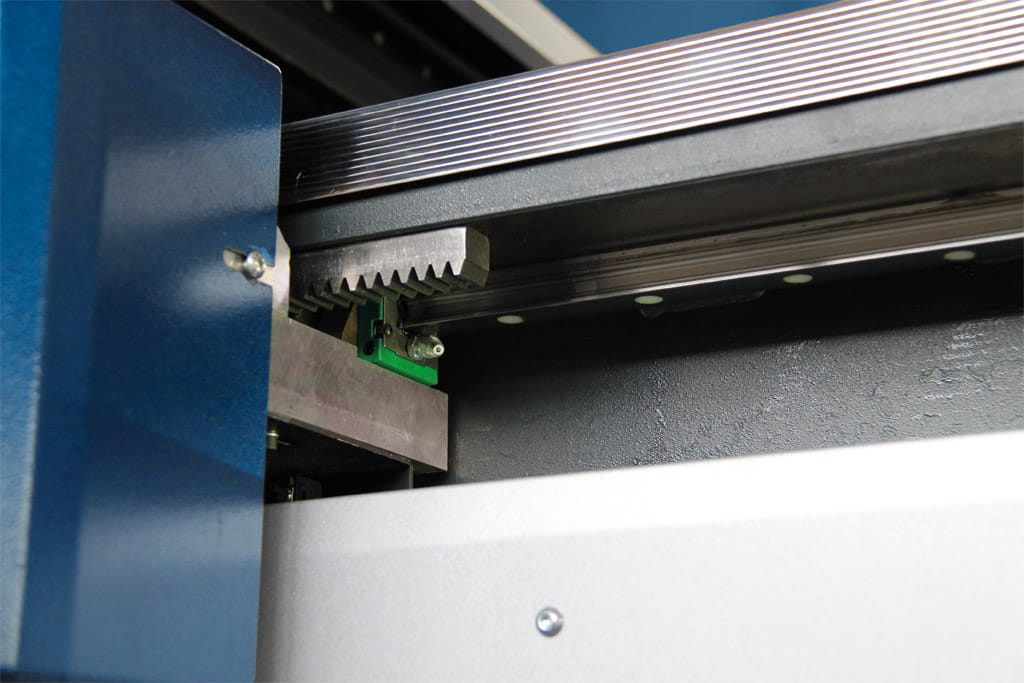

In the side rail are located, like in all Hpm machines, prismatic guides and rectified racks; in the upper part, where the crossbeam slides, the center of gravity allows a perfect balancing, which is useful for the accelerations and for cutting accuracy. The CNC and the electronic part “D.Electron” ensure the machine to be efficient, reliable and easy to be managed.

The bench for the laying of the sheet is separated from the rails and is divided in suction segments with shutters automatically controlled by the CNC. The upper part of the table consists of frames or grid sectors of several models, selected according to the type of accessories that compose the machine.

Steel Max, like all the other HPm models, besides quality, does not neglect the stylish details, that make it stand out within the workshops where it is used.

We use Brushless motors, high precision reducers, recirculating ball screws, rectified pinions and racks, runners and prismatic guides.

Steel Max is produced in cutting sizes of 1.5 - 2 - 2.5 - 3 - 3.5 meters in width, while even 40 meters in length.